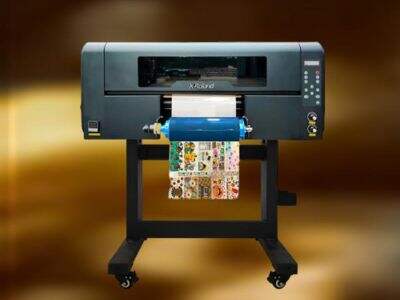

Ukuhlobana kwesilimini kungumxholo opheleleyo kwiNkcazo yeDTF UV. Isilimini esifuneka sinyathelwe sihlatyelwe kumgca wokunyathela ukuze kunyathelwe ngendlela efanelekileyo. Ukuhlobana kwesilimini kungumahluko-mkulu, okunokukhangelwa ngamaxesha amaninzi apha njengoko kuhlala kusenziwa kwiNkcazo yeDTF UV.

Indlela yokulungisa umgca osebenziswe kwiNkcazo yeDTF UV inemeko enkulu ekukhangeleleni isilimini.

Kumahla ukuba umgca ungachazi ngamanqina nezibani ngaphambi kokunyathela. I Mgqabi Omdala DTF Onesisweyo solvent okanye iindlela zokucula zinokusebenziswa ukucula nayiphi na into enguqukayo phezu kwesihlangothi. Ukuba une mfazwana omkhulu wokugqitha kunceda isilimini ukuba sihlobe ngakumbi kumgca, ukuze xa unyathela—kubonakale ngokucacileyo kwaye akungabonakali ngokupheleleyo.

Ngaphezu koko, ubomi bendalo nobunzima bwegazi bubaluleke kakhulu xa kufika kokuqhathaniswa kwesilimini kwiNkcazo yeDTF UV.

Ngaphakade kwiinxalenye eziphakadeyo, zizime kakhulu iiflim ayabondisa ngayo isiqhamo sakho, kodwa ukuba ziphantsi kakhulu, uzakuxhasa nokuphulwa kwemfazwe. Ubungakanani bokumkqamayo buqhagamshela nezibopho zokubonda kweflim ukuba ibonde kwi substrate. Ngolowo xabiso, ukulawula ubomi bokunxusana nobungakanani bokumkqamayo kwindawo yokuprinta kuyinto ekufunekayo ukuze uphumelele kubomi bomgangatho wokubonda kweflim.

Enye into eyisiseko kukusebenza kwesayensi sokugcina ink: ukususwa kwegazi kuyinto ekufunekayo ukuze kube lula ukubonda kweflima kwi-UV DTF printing. Ubomi obukhanyayo bukhokelela kumgangatho ophezulu xa igazi igcinwe ngendlela efanelekileyo kwi substrate. Iflim akunakubanda kuyo, kwaye ubomi bokuprinta buya kuphazanyiswa ukuba igazi ayigcinwanga ngendlela efanelekileyo. Ukuqinisekisa ukubonda okuhle kweflim kuthintelwe ukulandela ixesha nesimo sobomi sokugcina igazi ngumthengi.

Umboniso wesiqhamo ungalahla ngempande yokuqhubeka kweflima kwiindlela zokuprinta ze-UV DTF.

Izihlengahlenga ziyahlukile ngokwezenzo zezandla kwaye ziya kuthintela umgca opholileyo. Unxibelelwano oluhle lunakalwa ngokukhetha i-substrate enentshombo ne mgca kunye nesicelo esisetyenzisiweyo. Ukuhlola iindawo ezahlukeneyo ziya kunceda ukufunda okanye yintoni eyiyo efunekayo kumsebenzi wokuprinta.

Ngokomzekeliso wophango lwe mgca kwi- DTF UV printing, into enye ebanziyo kungumthwalo wesicelo. Izenzo zesicelo zithatha njani xa zizakhiwe phezu kwesihlengahlenga kwaye emva koko zixhakeke kumgca. Kusebenza ngokokulungiswa komgama ngoba amagama akunakho kugcinwa kakuhle ukuba isicelo sikhulu kakhulu okanye sibalulekile. Oku Iprinta lwe-UV DTF umsindo uza kunceda ukufumanisa iindlela ezilungileyo zomthwalo wesicelo zonke zilandelayo unxibelelwano oluhle lwemgca.

Ukuphawula

Kukho iindawo ezininzi ezingathint' ubunzima bokudibanisa kwefilimu kwi-UV DTF printing. Ubunzima bokudibanisa kufanelekile buqondene nendawo eyiyo, njengeendlela zokulungisa umgodi, ubomi bendawo kunye nomthubi, inkcazo yamanzi, ukugcina kwesayensi okanye ubunzima befilimu. Ngokubophelela kwezo zinto kwaye uwenze utshintsho olufunekayo, umprinter unokufumana imifanekiso emnandi enobunzima obugcwele befelimi. Ngoba ngumkhiqizo ophakade Iprinta lwe-DTF umkhiqizo, uJihui Electronic uphinde aphinde amanyathelo afaneleyo abalulekileyo kumaprinta afuna ukufumana iziphumo ezilungileyo xa esebenzisa i-techniques ze-DTF UV printing.

Tafula yeengcango

- Indlela yokulungisa umgca osebenziswe kwiNkcazo yeDTF UV inemeko enkulu ekukhangeleleni isilimini.

- Ngaphezu koko, ubomi bendalo nobunzima bwegazi bubaluleke kakhulu xa kufika kokuqhathaniswa kwesilimini kwiNkcazo yeDTF UV.

- Umboniso wesiqhamo ungalahla ngempande yokuqhubeka kweflima kwiindlela zokuprinta ze-UV DTF.

- Ukuphawula