The adhesion of the film is a very important part in the DTF UV printing process. The film that needs to be printed is stuck on the substrate for better printing. Film adhesion is one of the crucial elements, which could be influenced by many factors during film adhesive procedure in DTF UV printing.

The surface preparation technique used in DTF UV printing plays a big role on the adhesion of film.

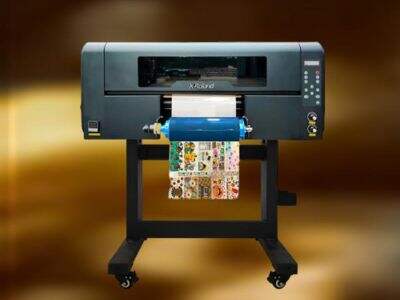

It is essential that the substrate is dirt and dust free before printing. The All-in-one DTF Printer solvent or cleaning agents can then be used to clean up any surface contaminants. Having a high coefficient of friction can help the film adhere better to the substrate ensuring that when you print — it is clear and not dull.

Also, the temperature and humidity play a significant role when it comes to film adhesion in DTF UV printing.

The higher the temperatures better the film will bond with your substrate, but if it is very low, then you will experience lifting or peeling problems. Relative humidity also links to the adherence ability of the film to stick on the substrate. In this regard, controlling the temperature and humidity of the print environment is essential to obtain good adhesion of the film.

Another important thing is correct ink curing: the appropriate drying of the ink is also essential for improving film adhesion in DTF UV printing. The bond is strong if the ink has been correctly cured on the substrate. The film may not stick to it and the print quality will suffer if the ink is not properly cured. Good film adhesion is ensured by adhering to the manufacturer's ink curing time and temperature.

Substrate composition may also have an effect on film adhesion in the DTF UV printing process.

Substrates are different in surface properties and will alien the wet film as well. Best adhesion can be achieved by selecting a substrate that is compatible with the film and ink used. Testing of various substrates will help you to realize which one is suitable for particular printing work.

Regarding film adhesion in DTF UV printing, another crucial factor would be the ink viscosity. The properties of the inks are influences how easily they spread over a substrate and later bind to the film. Applies in terms of quality as text will not take properly if the ink is too thick or to thin. This UV DTF printer process will help you determine the best ink viscosity levels that promote excellent film adhesion.

Conclusion

There are too many factors that affect the adhesion of film in DTF UV printing. Optimal film adhesion is dependent on a number of factors such as surface preparation techniques, temperature and humidity levels, ink curing, substrate composition or ink viscosity. By attending to these considerations and making adjustments as necessary, the printer can achieve good prints with excellent film integrity. As a leading DTF printer manufacturer, Jihui Electronic offers the most effective solution for printers wanting to get optimum results when using DTF UV printing techniques.

Table of Contents

- The surface preparation technique used in DTF UV printing plays a big role on the adhesion of film.

- Also, the temperature and humidity play a significant role when it comes to film adhesion in DTF UV printing.

- Substrate composition may also have an effect on film adhesion in the DTF UV printing process.

- Conclusion